Pouring Cement Sidewalk

Pouring cement sidewalks may seem daunting, but with careful planning and execution, creating a durable and attractive walkway is achievable. This guide provides a step-by-step process, from initial ground preparation to the final finishing touches, ensuring a successful project. We’ll cover essential techniques, material considerations, and crucial safety precautions to help you navigate each stage confidently.

From understanding the ideal cement mix ratios and achieving the perfect consistency to mastering leveling techniques and employing proper curing methods, this guide offers a detailed roadmap for creating a beautiful and long-lasting sidewalk. We’ll explore various design options and address common problems, equipping you with the knowledge to overcome any challenges you might encounter.

Cement Sidewalk Construction: A Comprehensive Guide

Source: ytimg.com

Building a durable and aesthetically pleasing cement sidewalk requires careful planning and execution. This guide provides a step-by-step approach to constructing a sidewalk, covering everything from ground preparation to finishing and curing. We will explore essential techniques, common pitfalls, and design considerations to help you achieve a successful project.

Cement Sidewalk Preparation

Proper ground preparation is crucial for a stable and long-lasting sidewalk. A solid, level base prevents cracking and settling over time. This involves removing existing vegetation, excavating to the required depth, and compacting the base material thoroughly.

Creating a level base is achieved through careful grading and the use of a level to ensure a consistent surface. Proper compaction of the base material, typically compacted gravel or crushed stone, is essential to prevent future settling and cracking. This is often done using a plate compactor or hand tamper.

The following tools and materials are necessary for effective ground preparation:

| Tools | Materials | Tools | Materials |

|---|---|---|---|

| Shovel | Gravel or Crushed Stone | Level | Compacted Sand (optional) |

| Rake | Geotextile Fabric (optional) | Plate Compactor or Hand Tamper | Wooden Stakes and String (for layout) |

| Measuring Tape | Line Level |

Cement Mixing and Consistency, Pouring cement sidewalk

Source: familyhandyman.com

The correct ratio of cement, sand, and gravel is critical for achieving the desired strength and workability of the concrete mix. The water content significantly impacts the final strength and workability; too much water weakens the concrete, while too little makes it difficult to work with.

Mixing can be done manually using a shovel and wheelbarrow, or mechanically using a cement mixer. The ideal consistency is a workable, slightly sticky mix that can be easily poured and leveled without excessive segregation of materials. It should be uniformly moist and hold its shape when a small amount is scooped up and allowed to slump slowly.

A common mix ratio is 1 part cement, 2 parts sand, and 3 parts gravel. However, this can vary depending on the specific requirements and the type of cement used. Always follow the manufacturer’s instructions for the best results.

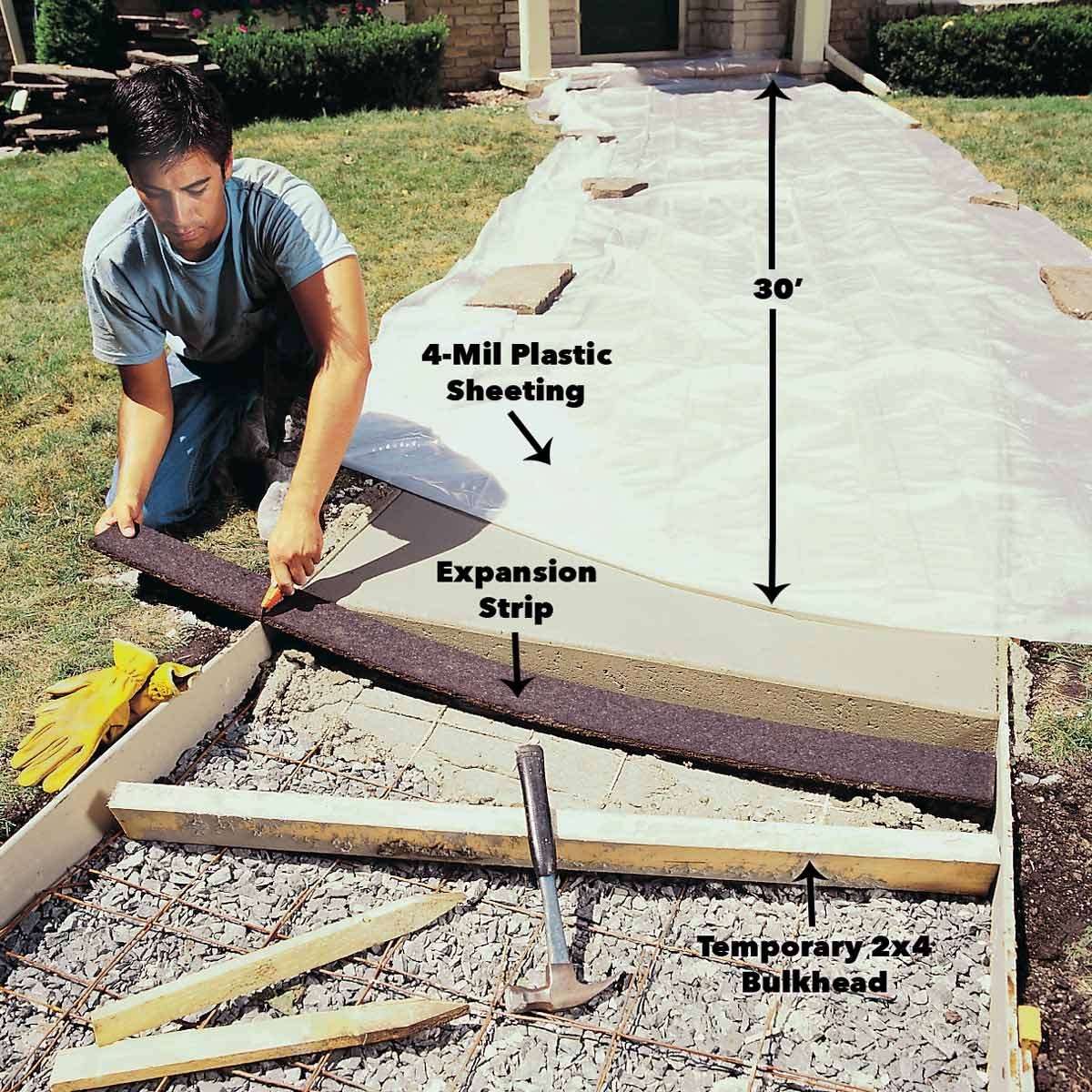

Pouring and Leveling Techniques

Source: familyhandyman.com

Pouring cement into the forms should be done evenly and consistently to prevent voids and ensure a level surface. Screeds are used to strike off the excess concrete to create a level surface, while bull floats smooth out the surface and eliminate minor irregularities.

The following steps Artikel the pouring and leveling process:

- Pour the concrete into the forms, working from one end to the other.

- Use a screed to strike off the excess concrete, ensuring a level surface.

- Use a bull float to smooth the surface and eliminate any minor irregularities.

- Allow the concrete to begin setting before proceeding to the finishing stage.

Finishing and Curing

Source: pinimg.com

Proper finishing techniques are essential for a durable and aesthetically pleasing sidewalk. This involves using a trowel to create a smooth surface and potentially adding textures for improved slip resistance. Curing is the process of keeping concrete moist for a time to allow it to gain strength and durability. This can be achieved through the application of curing compounds or by keeping the surface consistently moist with water.

Different troweling techniques can achieve various surface finishes, from a smooth, polished look to a more textured surface. Curing compounds help retain moisture and prevent cracking, contributing to the overall longevity of the sidewalk.

Common Problems and Solutions

Source: cloudfront.net

Common problems during sidewalk construction include cracking, uneven surfaces, and scaling. Cracking often results from insufficient compaction of the base, improper mixing, or rapid drying. Uneven surfaces are usually due to inadequate leveling during the pouring process. Scaling can be caused by using low-quality cement or improper curing.

Solutions involve addressing the underlying causes. For example, cracking can be mitigated by ensuring proper base compaction and using expansion joints. Uneven surfaces can be corrected by re-leveling or using a self-leveling compound. Using high-quality materials and proper curing techniques can prevent scaling.

Sidewalk Design Considerations

Sidewalk designs can vary significantly in width, texture, and edging. Three examples include a standard 4-foot wide sidewalk with a smooth finish and simple edging, a wider 6-foot sidewalk with a textured surface for improved slip resistance and decorative edging, and a narrow 3-foot path with exposed aggregate finish and natural stone edging.

The standard design is cost-effective and suitable for most applications. The wider sidewalk with textured finish offers enhanced safety and aesthetic appeal but at a higher cost. The narrow path with exposed aggregate provides a unique look and blends well with natural surroundings, while the cost is comparable to the standard design.

Tools and Equipment

Source: pressablecdn.com

Various tools and equipment are essential for successful sidewalk construction. These can be categorized into mixing tools, finishing tools, and compaction equipment.

| Category | Tool | Function | Usage |

|---|---|---|---|

| Mixing | Cement Mixer | Mixes cement, sand, and gravel | Used for larger projects |

| Mixing | Shovel | Mixes concrete manually | Used for smaller projects |

| Finishing | Screed | Levels the concrete surface | Used after pouring |

| Finishing | Bull Float | Smooths the concrete surface | Used after screeding |

| Compaction | Plate Compactor | Compacts the base material | Ensures a stable base |

| Compaction | Hand Tamper | Compacts the base material manually | Used for smaller areas |

Safety Precautions

Safety is paramount during sidewalk construction. Personal protective equipment (PPE), including safety glasses, gloves, and boots, should always be worn. Proper handling of materials, including avoiding contact with skin and eyes, is crucial. Working conditions should be safe and free from hazards.

Specific precautions include avoiding working in extreme weather conditions, using proper lifting techniques to prevent injuries, and ensuring the work area is properly secured to prevent accidents. Always follow local safety regulations and guidelines.

FAQ: Pouring Cement Sidewalk

What type of cement is best for a sidewalk?

Portland cement is the standard and most suitable type for sidewalk construction due to its strength and durability.

How long does cement take to dry completely?

Initial setting occurs within a few hours, but complete curing, reaching full strength, can take several weeks, depending on weather conditions.

How can I prevent cracks in my sidewalk?

Proper base preparation, using control joints (expansion joints), and ensuring adequate curing are crucial for preventing cracks.

What is the best weather for pouring cement?

Ideal conditions are moderate temperatures (between 50°F and 80°F), with no rain expected for at least 24 hours after pouring.

Can I add color to my cement sidewalk?

Yes, integral color pigments can be added to the cement mix to achieve various colors. Follow the manufacturer’s instructions for proper mixing ratios.

Comments are closed.