Cost Of Cement Walkway

The cost of cement walkway projects varies significantly depending on numerous factors. Understanding these factors is crucial for budgeting and planning your project effectively. This guide explores the key elements influencing the overall cost, from material selection and labor considerations to regional differences and design complexities. We’ll delve into a detailed breakdown of each component, empowering you to make informed decisions throughout the process.

This comprehensive analysis will equip you with the knowledge necessary to estimate the cost of your cement walkway accurately. We will examine various scenarios, highlighting the impact of different choices on your final budget. By understanding the intricacies of material costs, labor expenses, and regional variations, you can confidently navigate the planning phase and ensure a successful outcome.

Factors Affecting Cement Walkway Costs

The cost of a cement walkway is influenced by a variety of factors, making it crucial to understand these elements before embarking on your project. A detailed understanding allows for accurate budgeting and informed decision-making regarding materials, labor, and design choices. This section provides a comprehensive breakdown of these key cost drivers.

Factors Influencing Cement Walkway Prices

Several factors significantly impact the final cost of your cement walkway. The following table illustrates these factors, their descriptions, and their influence on the overall cost, and provides concrete examples.

| Factor | Description | Impact on Cost | Example |

|---|---|---|---|

| Materials | Type and quantity of cement, aggregates (sand, gravel), and additives. | Higher quality materials increase the cost. | Using high-strength cement versus standard Portland cement. |

| Labor | Cost of skilled labor for excavation, formwork, pouring, finishing, and curing. | Higher labor rates in certain regions or for specialized work increase costs. | Hiring a specialized finisher for intricate patterns versus a general contractor. |

| Location | Geographical location influences material and labor costs. | Remote locations with higher transportation costs increase overall expenses. | A walkway was built in a rural area versus one in a densely populated city. |

| Design Complexity | Intricate designs, curves, patterns, and decorative elements add to the labor and material costs. | Simple designs are less expensive than complex ones. | A simple, straight walkway versus a curved walkway with stamped concrete patterns. |

Cement Types and Cost Variations

The type of cement used directly impacts the project’s cost and durability. Different cements offer varying properties and price points.

- Portland Cement: The most common type, offering good strength and workability. Typical price range: $80-$150 per ton.

- High-Strength Cement: Provides superior strength and durability, ideal for high-traffic areas. Typical price range: $120-$200 per ton.

- Rapid-Setting Cement: Sets and hardens quickly, suitable for projects requiring fast completion. Typical price range: $100-$180 per ton.

- Colored Cement: Adds aesthetic appeal but is generally more expensive than standard cement. Typical price range: $150-$250 per ton.

Simple vs. Complex Walkway Cost Comparison

Consider a hypothetical scenario comparing a simple 10ft x 5ft straight walkway versus a complex 10ft x 5ft walkway with curves and stamped patterns. The simple walkway would require less material and labor, resulting in a lower cost. The complex walkway would necessitate more skilled labor, specialized tools, and potentially more expensive materials, leading to a higher overall price.

Material Costs: Cement, Aggregates, and Additives

Understanding the cost of individual materials is essential for accurate budgeting. This section details the materials required for a typical cement walkway and their associated price ranges.

Cement Walkway Material List

The following list of Artikels the key materials needed, their typical quantities for a small walkway (approximately 100 sq ft), and their price ranges. Note that prices can vary significantly based on location and supplier.

- Cement (Portland): 1-2 tons, $80-$300 (depending on type and quantity)

- Sand: 1-2 cubic yards, $20-$50 per cubic yard

- Gravel: 1-2 cubic yards, $30-$60 per cubic yard

- Water: As needed (cost negligible)

- Additives (Optional): $10-$50 per bag (depending on type and quantity)

- Form Lumber/Metal: Cost varies greatly depending on size and material, $50-$200

Aggregate Cost Variations

The cost of aggregates (sand and gravel) can vary based on their source, quality, and type. Generally, gravel is slightly more expensive than sand due to its larger size and potentially higher transportation costs.

Impact of Cement Additives

Source: concretenetwork.com

Cement additives can enhance the walkway’s properties (e.g., workability, strength, durability). While they add to the overall cost, the benefits often outweigh the additional expense, especially in demanding applications.

Labor Costs and Contractor Fees

Labor costs represent a significant portion of the total project expense. This section details the labor involved and how contractor fees are structured.

Labor Components in Cement Walkway Construction

Building a cement walkway involves several labor-intensive tasks. The following table illustrates these tasks, their descriptions, typical hourly labor costs, and estimated time requirements for a small walkway.

| Task | Description | Typical Labor Cost per Hour | Estimated Time Required (Small Walkway) |

|---|---|---|---|

| Excavation | Digging and preparing the base. | $40-$60 | 2-4 hours |

| Formwork | Building and setting up the forms. | $40-$60 | 4-6 hours |

| Pouring | Pouring the cement mixture into the forms. | $40-$60 | 2-3 hours |

| Finishing | Leveling, smoothing, and texturing the surface. | $50-$75 | 6-8 hours |

| Curing | Protecting and maintaining the newly poured cement. | $30-$40 | 1-2 days (minimal labor) |

Contractor Fee Structure and Influencing Factors

Contractor fees are typically based on an hourly rate, a per-square-foot rate, or a fixed price. Factors influencing pricing include the contractor’s experience, location, project size, and complexity of the design.

DIY vs. Hiring a Contractor

Source: landscapingnetwork.com

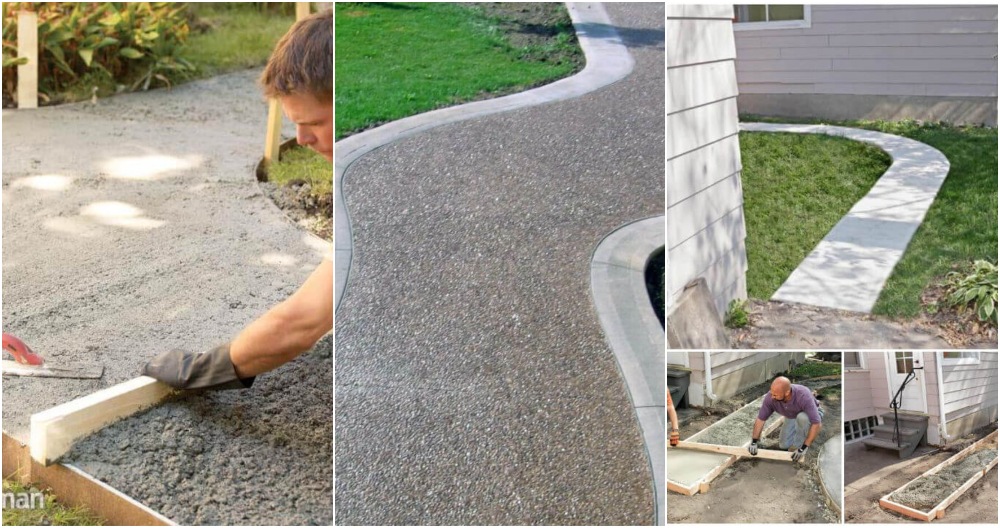

Doing it yourself can save on labor costs, but requires time, skills, and appropriate tools. Hiring a contractor offers expertise and convenience but comes at a higher cost. Weighing the time commitment, potential risks, and skill level is crucial when making this decision.

Regional Variations in Cement Walkway Costs

Source: pinimg.com

The cost of a cement walkway varies significantly depending on geographical location. This section compares costs across different regions and explains contributing factors.

Regional Cost Comparison

The following table provides a comparison of average costs for a standard 100 sq ft cement walkway in three different regions. Note that these are estimates and actual costs can vary.

| Region | Average Cost | Contributing Factors |

|---|---|---|

| Northeastern US | $1500-$2500 | Higher labor costs, and potentially higher material costs due to transportation. |

| Southern US | $1200-$2000 | Generally lower labor costs, potentially lower material costs in some areas. |

| Midwest US | $1300-$2200 | Moderate labor and material costs. |

Impact of Local Regulations and Permits

Source: com.au

Local regulations and permit requirements can add to the overall cost. Permits are often necessary for larger projects or those involving significant excavation or changes to existing landscapes.

Seasonal Cost Fluctuations

Material and labor costs can fluctuate seasonally. Labor costs may be higher during peak construction seasons, and material costs may be affected by weather conditions and availability.

Design and Size Considerations

Source: diycraftsy.com

The size and design of your walkway significantly influence the final cost. This section explores how these factors impact the overall expense.

Walkway Design and Cost Implications

Source: pinimg.com

The size (length and width) directly impacts the quantity of materials and labor required. More complex designs, such as curved walkways or those with intricate patterns, require more skilled labor and potentially specialized tools, leading to increased costs.

Design 1: Simple Straight Walkway: A basic, straight walkway with uniform width requires minimal materials and labor, resulting in the lowest cost. Imagine a simple rectangular path.

Design 2: Curved Walkway: A curved walkway requires more precise formwork and potentially more cement to accommodate the curves. This increases both material and labor costs.

Design 3: Walkway with Patterns and Borders: Incorporating decorative elements like stamped patterns, borders, or colored cement significantly increases the cost due to the specialized labor and materials involved. This option adds visual interest but increases the complexity of the project.

Cost of Decorative Elements

Adding decorative elements, such as borders, patterns, or colored cement, enhances the aesthetic appeal but adds to the overall cost. Stamped concrete, for example, requires specialized tools and expertise, increasing labor costs.

Straight vs. Curved Walkway Cost Comparison, Cost of cement walkway

Consider a 20-foot-long walkway. A straight walkway will require less material and labor than a curved walkway of the same length. The curved walkway’s increased complexity translates to higher costs for both materials and labor.

Commonly Asked Questions: Cost Of Cement Walkway

Can I install a cement walkway myself?

While possible, DIY installation requires significant time, effort, and specialized tools. Hiring a professional often proves more cost-effective in the long run, minimizing risks of mistakes and ensuring a quality finish.

What is the typical lifespan of a cement walkway?

With proper installation and maintenance, a cement walkway can last for many years, often 20-30 years or more. Regular sealing helps protect it from weathering and damage.

What happens if I need permits for my walkway?

Permitting requirements vary by location. Check with your local authorities early in the planning process to understand any necessary permits and associated fees. Delays due to permitting can impact project timelines.

How do I choose a reputable contractor?

Seek recommendations, check online reviews, and obtain multiple quotes. Ensure the contractor is licensed, and insured, and provides a detailed contract outlining the scope of work and payment schedule.

Are there environmentally friendly cement options?

Yes, several manufacturers offer cement with reduced carbon footprints, incorporating recycled materials or utilizing alternative production methods. These options may have slightly higher initial costs but contribute to sustainability.

Comments are closed.